AiRTX Vortex Tubes (review)

A Vortex Tube (or Ranque-Hilsch Vortex Tube - RHVT) is a device that transforms a compressed air flow into two flows, one very cold and one very hot. It doesn't require electricity or mechanical components with moving parts. For this reason it is used to obtain instant cold air (about -40°C) for localized cooling in industrial applications, or hot air (about 110 °C) for localized heating: all this starting from a single flow of compressed air.

AiRTX International produces the best Stainless steel Vortex Tubes, and the simple and reliable stainless steel AiRTX Vortex tube ensures high quality and is sold at the same price of other producers of Aluminum Tubes.

Main features

- Instant Cold or Hot Air - from -40°F to 230°F - From Ordinary Compressed Air

- Vortex Tubes from AiRTX — Precision Stainless Steel for the Price of the "Other Guys" Aluminum Tubes

- Starting with corrosion-resistant, food-grade Stainless Steel as the principal material of construction, AiRTX designers have optimized every aspect of Vortex Tube design for convenience, dependable performance, and long-lasting service.

- The AiRTX Vortex Tube is as good-looking as it is functional. It’s precision machined, assembled and tested.

- Manufactured to exacting tolerances, AiRTX Vortex Tubes are produced under strict quality control to ensure years of reliable, maintenance-free operation.

Vortex Tube Advantages

- Vortex tubes have no moving parts, are portable & lightweight and low cost.

- They use no electricity, freon or chemicals; just filtered, factory compressed air.

- Vortex tubes have no spark hazard, RF/EMI interference.

- Instant on/off, easy to control, cools without waste.

- No residue to clean up, no parts washing needed.

- Reliable, maintenance-free, durable Stainless Steel construction.

- Input air flows of 8, 10, 15, 25, and 35 cfm (220,280,420, 700, 990 lpm); up to 2800 BTU/H (630 Kcal/H) cooling capacity.

What is a Vortex Tube and how does it work?

Vortex Tube, also called Ranque-Hilsch Vortex Tube or cooling tube, is the most efficient way to obtain instant cold air, wherever it is needed, by using ordinary compressed air. No electricity nor moving parts are required, it doesn't require any maintenance service, and there is no risk of explosion. It allows to obtain clean cold air for inexpensive spot cooling for industries or laboratories.

It was invented by the French physicist Georges J. Ranque, who developed the first Vortex Tube in 1930, trying to obtain cold air from a stream of compressed air.

A Vortex Tube splits compressed air into two vortices: the first very cold and the second very hot, without moving components. It is a very simple and inexpensive tool and it can provide:

- temperatures from - 40 °C to + 110 °C

- 2.800 BTU/H (630 Kcal/H) maximum of refrigeration

- 990 litres/min airflow

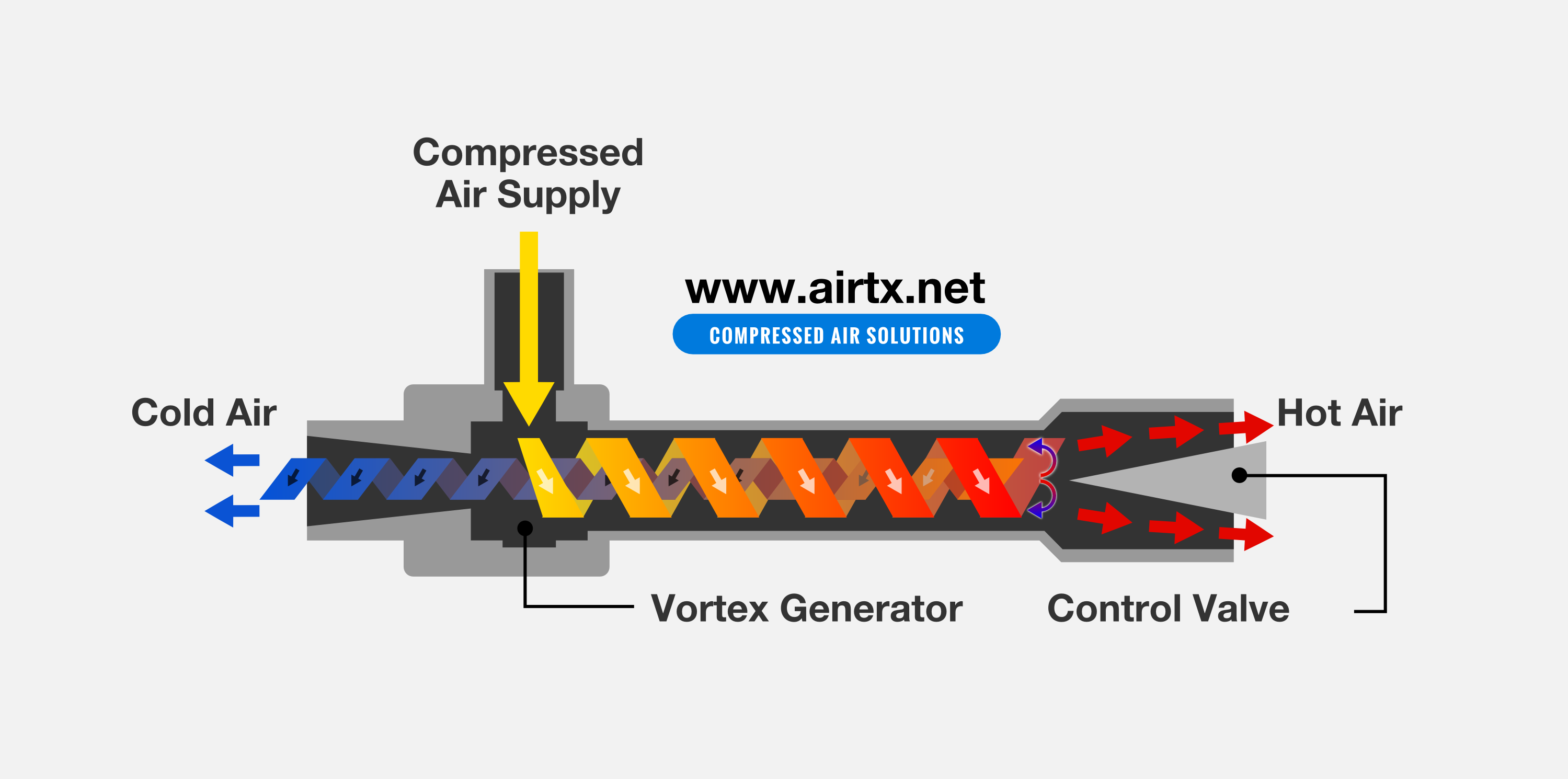

The basic principle is simple: when the compressed air is pushed into the tube, it goes through a vortex generator and it exits from the two ends: cold air at one side, hot air at the other. A small control valve in the hot air exhaust allow the control of temperatures, flows and refrigeration over a wide range. The generator is a stationary element and can be changed: it adjusts the quantity of the incoming compressed air, and this determines the quantity and the temperature of the final airflows.

Stainless steel Vortex Tubes allow, thanks to a control valve and a thermometer, to check and control the cold air without any other instrument.

If the temperature and the pressure of the compressed air are constant, the Vortex Tube keeps a regular final temperature - within a range of ± 0,6 °C.

A single interchangeable component, the "Vortex Generator", allows to change the flow and to have, with the same Vortex Tube, five different types of airflows:

- 220 litres/min

- 280 litres/min

- 420 litres/min

- 700 litres/min

- 900 litres/min

AiRTX Vortex Tubes: complete systems, "Tube only" and "Application Development Kit"

The simple and reliable stainless steel AiRTX Vortex tube ensures high quality and is sold at the same price of other producers of Aluminum Tubes.

It is made of stainless steel, for applications in the food industry, corrosion resistant: AiRTX designers and engineers optimized every aspect of the Vortex Tube in order to have reliable and long-lasting performances.

AiRTX Vortex Tubes are extremely precise tools, tested with utmost care. They have to pass high level quality controls to ensure years of working without any kind of maintenance.

AiRTX offers Vortex Tubes in different configurations, ready to use for the most common industrial operations. These systems include "Cold Air Gun" model 60040 and Cabinet Cooler.

AiRTX offers an "Application Development Kit", for planners and engineers that need to study, project, develop and test machines for the production. Changing one of the pieces included in the kit, it will be possible to create a wide range of streams of air, especially cold air, that the Vortex Tube can generate. The Development Kit includes:

- instructions;

- one 5 micron air filter

- one silencer

- 8 vortex generators

- one hose for directing the cold air flow

It is possible to buy the Vortex Tube alone, or with other components for optimizing your own personal application.

Two Vortex Tubes, ten levels of performance

AiRTX designs its Vortex Tubes in a modular way, so as to obtain ten different kinds of performance from a single Vortex Tube, by simply changing the "Vortex Generators". These are sold in two versions that differ according to the level of cooling capability. Both versions, "high cold fraction" and "low cold fraction", are available for 220, 280, 420, 700 and 990 litres/min compressed air flows. It is possibile to buy every "Vortex generator" singly or in a kit that contains all of them.

The simple and reliable stainless steel AiRTX Vortex tube ensures high quality and is sold at the same price of other producers of Aluminum Tubes.